Modern industrial equipment and manufacturing processes require a diverse range of precision materials to achieve the pinnacle in efficiency. Whether you’re manufacturing industrial storage tanks or looking to restore your gear wheels with durable steel, our team can help. Find out why Specialty Steel Treating is your premier resource for tempering steel.

Steel Tempering Process

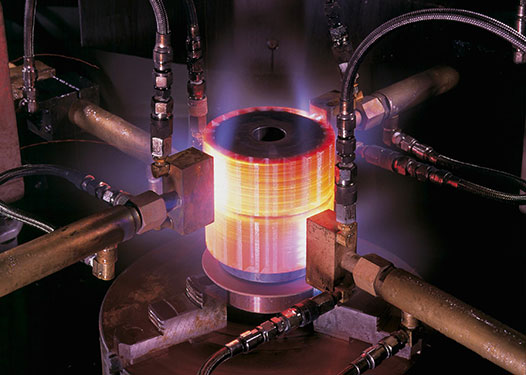

The process begins with steel. While there are many different metals that can be tempered, steel is valuable for its strength and resistance. Once you’ve selected your grade and steel or another iron-based alloy, the process of tempering steel begins with extreme heat.

Once the steel is heated sufficiently, it’s rapidly cooled. While the theory behind steel tempering is simple, the entire process is incredibly precise. The exact temperature requirements, cooling temperature, cooling method and speed all require extreme care to ensure the steel heat treatment process is carried out in a stable and even manner.

This entire process of heating and rapidly cooling is also called quenching or oil quenching. Quenched steel is incredibly hard, but lacks the ductility required for many applications.

Tempering steel is the process of slowly, accurately reheating the quenched metal to achieve the desired balance of ductility and hardness.

Any irregularities in the steel when incorporating this process results in warped, distorted and damaged materials. These distortions compromise the overall integrity of your tempered steel, so it’s critical to choose a service provider who is experienced in precision tempering.

It’s essential to carry out the steel tempering process immediately after your steel has been quench hardened. This ensures that the structure isn’t compromised by the brittleness of quenching.

Because of the quick turnaround of these interrelated processes, it’s essential to choose a heat treatment service provider who is able to achieve both aspects of steel treatment for your custom components.

Advantages of Tempering Steel

There are many excellent reasons to choose tempered steel over other alloys. Depending on your industry, you can enjoy various grades and thicknesses to meet your exact standards. Here are a few competitive advantages you can enjoy when you choose tempered steel:

- Less brittle

- Increased ductility

- Easily weldable

- Improved abrasion resistance

One of the biggest advantages of utilizing this process with stainless steel is the wide range of variance available. From extremely durable quenched steel to highly ductile tempered steel, our expert process can achieve the perfect balance for your needs. Each of these levels of customization is classified as a grade, typically from 80 grade to 400 grade.

Without tempering steel, your stainless steel and other alloys won’t enjoy the same level of ductility and weldable properties. Instead, quenched steel that isn’t tempered is often too brittle to work with and too hard to reposition into your desired application.

Common Applications

There are many industries that rely on tempering steel for their equipment needs. Here are just a few applications that could apply to your industry:

- Bridge and building construction

- Durable storage tanks

- Cutting edges for drills and saws

- Liners for trailers, dump trucks and chutes

- Gears

- Deflector plates

Because Specialty Steel Treating is one of the leading heat treatment service providers in the industry, we can customize the quenching and tempering process to fit your needs. No part is too large or small, and we can accurately reach your desired grade of tempering stainless steel or other alloy.

Specialty Steel Treating

If you’re ready to discover how tempered steel can improve your equipment or quickly restore your damaged parts, contact us today. At Specialty Steel Treating, we specialize in steel treatment options for a variety of industries.

From aerospace and automotive to firearms and heavy equipment, receive the precision components you need. Start a conversation with us today to learn how you can effectively utilize our variety of precision steel tempering services.